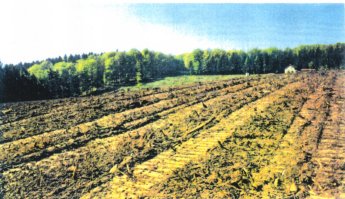

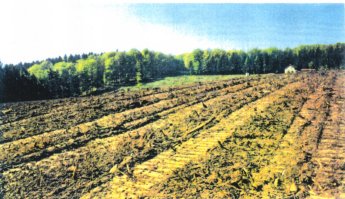

Proceeding of a clearing

The proposed markings, warning notices, safety areas and safety margins

are identically to the SOP of manual demining actions and are obligatorily

taken, used, and kept. The details are not described more exactly

here for they are considered as known to the experts.

KMMCS operates in two procedures:

1. Mechanical mine clearing operation by activating or destroying

functional and not functional mines and other combustible agents of

all kinds (bazookas, hand grenades, small rockets etc.) with the mill

of the machines I or II. Even at the way to the mine-suspected area

the machine has to mill its path with minimum of 20 cm depth.

2. Internal Quality Control with aftercare of the cleared area (visual

survey without neccessity for the person to have physical contact

to the soil and secure removal of not fully broken mine debris) with

machine III and the attachments disk harrow and Cambridge Roller.

The contractor exactly defines mine-suspicioned areas and minefields

by specification of the coordinates or by landmarks.

At mine-suspicioned areas Machine I or Machine II mills once.

Mine

fields on which several mines were found especially close to each

other are milled twice for safety reasons.

Both mine suspicion areas and mine fields are treated with following

Internal quality control. Mine suspicion areas are controlled once

with the machine III, mine fields several times.

The employed Machines I, II und III

Machine I and Machine II destroy explosives

Machine I and Machine II are equal. They are mostly used in minefields

together as a clearing unit, so in case of a defect the other machine

can rescue the broken one from the minefield in a safe manner.

This machine is equiped with a 3 m wide double-mill, rotating contrary

to the direction of the driving. It can work with an operating speed

of 1-3 km/h and, depending on need, with exactly pre-defined soil-depth

up to 50 cm.

All detonable mines explode during the de-mining process.

All undetonated personal mines and anti-tank mines and also other

objects like tree, trunks, bush, concrete parts and other similar

obstacles are all disintegrated.

The vegetation is evenly replaced back in the soil.

The

black and white painted stick shows the depth of 100cm to that the

white wooden shred have been evenly mixed from the surface by the

Krohn Machines into the full volume of the soil in this demonstration.

The white line shows the solid ground.

The UN requirements for depth is 20 cm for manual demining, but our

machines achieve with normal setup up to 50 cm working depth into

the soil. That exeeds up to 2,5× the normal working depth if needed.

The machines, which have 3 m wide twin roters, ploughs 50 cm overlapping

stripes through the complete volume of the minefield that is totally

overturned that way.

The driving at a minefield or a mine suspected area is allowed only

in conjunction of milling with minimum depth of 20cm.

At practical work was proven that only a small number of the mines

actually explode because the system destroys most mines from their

bottom before they have the chance to explode by the ignator, that

is at the top side.

Our machines protect the operating driver from explosion splinters

which are equivalent to 10kg TNT. The strongest Anti Tank-Mines (ATM)

known have a detonation power of 5-7kg TNT equiv., very rarely 10kg

TNT equiv.

In front of the machine a hollow charge of 6 kg TNTequiv. exploded

without damaging the machine.

Accidently existing mines with extreme thick case (approx. 1 cm cast-iron)

are all cut from their outer ignator, but may not be disrupted totally

on a mechanical manner.

These

UXO´s (UXOs - unexplosive objects, here MUXO´s) with thick steel case

and already separtated ignator are collected and destroyed in the

following working process, the Internal Quality Control with Aftercare,

to prevent the reuse.

Machine III for Quality Control

This machine serves as vehicle for the internal quality control and

helps the machines I and II in case of breakdown. The machine III

is only allowed to roll at the soil that already had been milled.

The machine III can have a different apperance to this picture.

Internal Quality Control with aftercare

After the mechanical demining with machine l or II ALL mines and UXO´s

are destroyed. The level of safety is even over 99,9%.

For security reasons an internal quality control with aftercare is

done.

Mechanical agriculture machines are used. They have to be adapted

to the local soil conditions for each project. As standard machine

is declared:

At machine III a combination of a disk-harrow (to turn the soil and

uncover hidden mine-fragments) and a Cambridge Roller (breaking up

earth-clod and flattening the area) is attached.

At the back of this combination over the full width of 3 m a platform

with 3 seats is located, from where 3 controllers can watch a strip

of 5 meters without touching the ground. Suspected pieces are marked

with colorspray. The Operation's Supervisor identifies the fragments

and decides how to waist them regarding the local regulations.

As far as necessary the fragment is milled by the machine l or II

and mechanically destroyed.

A minefield is treated several times with the combination attachment

and controlled.

Doing so the area is prepared for seed or planting.

Should the control detect a clearance fault, that is a mine with intact

ignator or other dangerous piece, that may explode by touch or pressure

(misshandling), that piece has to be marked and one machine mills

this area again.

In case there is an explosion the fragment is regarded as a clearance

fault and the area of 1 ha around this point has to be milled again.

In case there is no explosion then the marked piece is not regarded

as a clearance fault.

The control then certifies the area as free from dangerous explosives.

After this "Internal Quality Control with aftercare" the area is reported

as minefree and ready for final external certification to the customer.

The final external certification by the customer also can be done

at the last drive. By that the full 100% of the area can be controlled

by the authorities of the customer and not only some spots of 5-10%

of the area as usually done by manual demining.

The working speed of machine III is up to 6 km/h, the working width

is 3 m.

The field is free from mines and dangerous explosives now and can

be be certified by authorities from theMine Action Center.